VECAP – Voluntary Emissions Control Action Program

VECAP’s mission is to increase awareness of chemical handling processes throughout the value chain. It is a tool for increasing the understanding of chemicals management beyond existing legislation; promoting constructive dialogue with interested industries, regulators and stakeholders; and raising awareness of all those involved in the process. Since its inception, it has not only improved additive management practices in user industry facilities, but it has demonstrably reduced emissions. It is a recognized risk reduction measure with clear value added for users and regulators including the European Chemicals Agency.

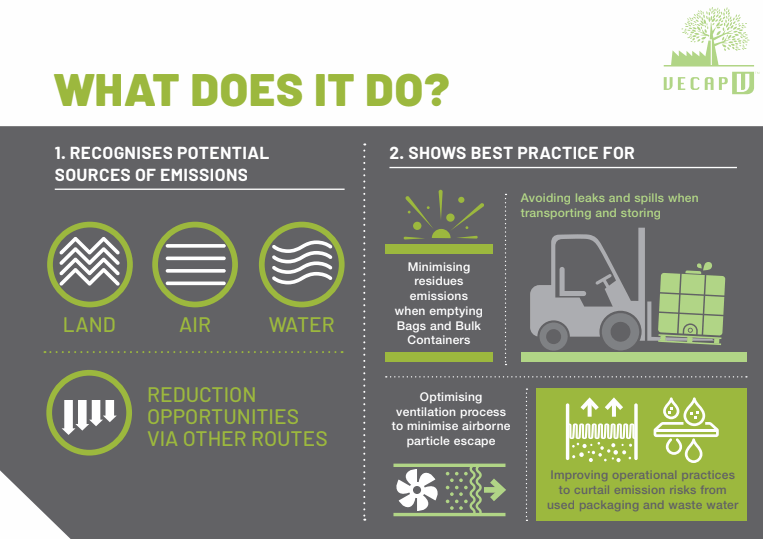

The aim is to minimise any release of additives into the environment.

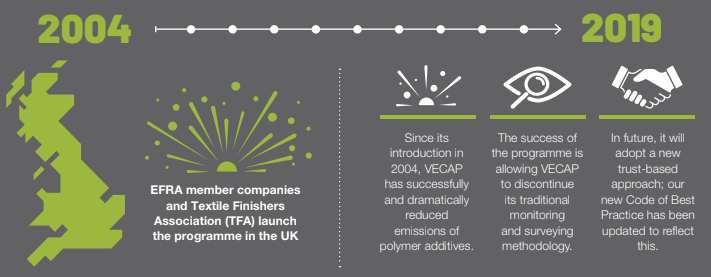

The original VECAP programme relied on data collection surveys to demonstrate that year on year trends of potential emissions had declined significantly. Additionally, the ranking system introduced more recently showed that a significant majority of the downstream users had implemented VECAP best practices, achieving a Gold or Silver rating.

Given this background, BSEF – The International Bromine Council, and its member companies, have decided to discontinue the traditional data collection via the surveys and take a new approach to promote VECAP as a valid risk reduction tool for users of brominated flame-retardant additives.

Over the years VECAP has evolved into a comprehensive system of chemicals management, which can be applied to a much wider range of processes and raw materials. View VECAP’s new Code of Best Practice