SAFR®-A Systematic Assessment for Flame Retardants

ICL’s approach to dealing with materials like flame retardants is fairly unique... They have taken an umbrella approach at designing and developing tools and an infrastructure to help customers evaluate the product choices and different applications. I find that very unique in the industry to be actually reaching out to the customers and providing tools to help assess the different possibilities in different choices."

John Warner, the president and CEO of the Warnerbabcock Institute for Green Chemistry (Nov 2019)

The SAFR® framework provides an evaluation of flame retardants in their applications, thus enabling users to select the most sustainable product for the intended use. By using the latest available scientific data and building on accepted hazard criteria, SAFR® incorporates an estimated exposure component based on the level of contact to humans and/or the environment and measurable potential emissions of flame retardants during their use.

As the SAFR® platform matures, ICL sees recognition and adoption, from clients and other business partners as well as leading professional institutes.

I hope that in the future we see ICL’s tools and methodologies find their way into different industry sectors, because I think it is a very useful approach.” John Warner, the president and CEO of the Warnerbabcock Institute for Green Chemistry (Nov 2019)

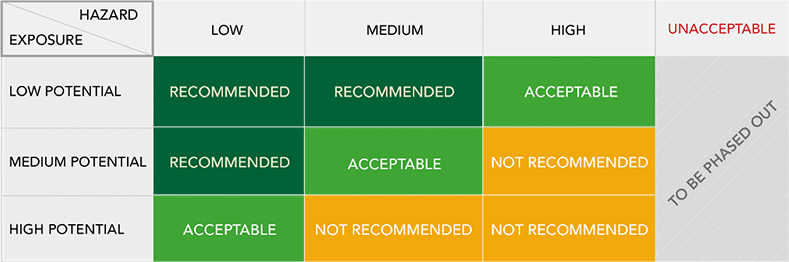

The assessment of a given flame retardant with SAFR® leads to the identification of:

- uses that are either recommended, acceptable or not

recommended, or - unacceptable hazard in which case alternatives should

be identified.

How we assess exposure

The SAFR® exposure assessment has a two-tiered approach. It considers both:

- The frequency of contact during the intended use (e.g. TV, computer, car seats, insulations boards);

- The potential emissions of the flame retardant used due to either migration to the surface (blooming), leaching or volatilization.

The methodology behind the SAFR® is available for any interested party upon request to ICL-IP. For more information please see the SAFR® website.

In Feb 2020, the SAFR methodology for measuring blooming was accepted as an ASTM as is now publicly available:

“Standard Test Method for Determination of the Blooming of Brominated Flame Retardants onto the Surface of Plastic Materials by

Ion Chromatography”, ASTM D8280.

A member of our value chain, Campine, together with ICL-IP, developed a similar methodology based on SAFR®, to assess the potential exposure to their product ATO, which is a synergist to FR.

Read More