Food Innovations & Alternative Proteins

ICL Food Specialties business brings over 75 years of experience to the food industry. The diverse ICL portfolio consists of high-quality functional phosphate and mineral systems to deliver buffering, pH adjustment, protein protection and shelf life enhancement across multiple markets, including Meat, Poultry, Seafood, Dairy, Beverage, Bakery, and Alternative Proteins.

Alternative Proteins

The ICL Food Specialties Team continues to expand its reach by recognizing the growing market for alternative proteins. ICL’s innovative technology enables the production of meat substitute products that are welcome alternatives to conventional meat products for flexitarians and health-conscious consumers who wish to reduce meat consumption without compromising taste or texture.

ICL’s innovative processing technology enables the production of meat substitute products.

ICL Food Specialties has won numerous awards for this technology, including the 2019 FI Innovation Award: Protein Category in Paris, France and the 2018 FiSA tradeshow “Most Innovative Ingredient” award in South America.

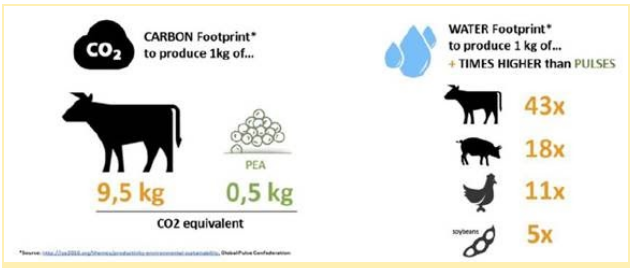

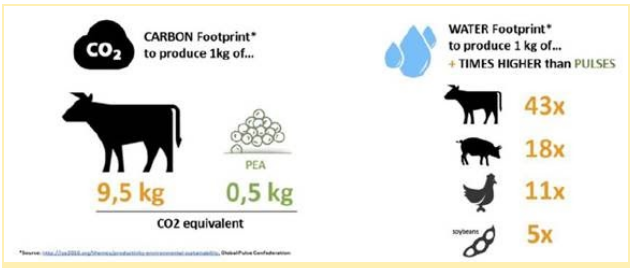

Along with the increasing challenges to our environment and climate are increasing public awareness and concern. Many consumers have reconsidered their habits to lessen their ecological footprint by reducing meat consumption and replacing food with meatless alternatives. Plant-based protein sources consume less water and produce less CO2 compared to the production of conventional animal protein, making them a more sustainable and less environmentally impactful food choice.

ICL recently decided to invest $18M to develop new capabilities dedicated to manufacturing plant-based fiber products.

Reducing Food Waste

Increasing Shelf-life

Processed Cheese Storage, “outside the fridge” with a guaranteed long shelf life. All spreadable processed cheese, made with ICL’s JOHA product range, can be stored outside the fridge, saving energy.

The exceptional shelf life (up to 2 years) permitted by the sterilization process and the use of JOHA salt, reduces food waste. This is highly relevant for emerging countries in which a closed cooling chain for food is not guaranteed. This also increases food safety. The longer shelf life makes dairy protein more accessible for a broader population.

Food Protein Savings in Dairy Industry

Each day, more than 1% of the production of an average cheese factory can’t be used in the end product and delivered to customers. This is caused by:

- Non-conform material lost due to processing conditions,

- Losses of cheese curd in the whey draining process,

- Non-sold cheeses nearing end of shelf life,

- Non-salable cheese from the packaging, cutting and grating processes.

ICL’s production processes can limit the loss in the cheese curd molding stage. Small pieces outside of the mold are normally lost (0.5% of the total cheese mass). ICL’s production process reuses all this otherwise wasted raw material, to produce processed cheese. This process permits keeping the high protein value of the cheese for human consumption. The accumulated material savings reduces both process waste and unnecessary pollution throughout the supply chain (as less raw material needs to be consumed).