Risk Management & The Precautionary Principle

Industrial production, in general, and the chemicals industry in particular, must take special precautionary measures to maintain a safe and healthy work environment. Several of ICL’s products, raw materials and production processes represent a potential risk to anyone who deviates from required professional safety standards or mandatory safety measures. ICL undertakes considerable efforts to ensure that it complies with the requirements of the authorities and acts in accordance with their instructions.

To ensure the safety of employees and others in its plants, ICL seeks to comply with strict occupational safety and health standards prescribed by local and international laws and standards. ICL invests extensive resources in training and mentoring, as well as other safety measures, in order to continually improve occupational safety and health and prevent accidents. ICL continues to enhance these procedures and measures and aims to become a top-tier organization in safety and environmental performance.

Regarding environmental issues, ICL’s commitment to the principles of the Responsible Care Global Charter serves to integrate the Precautionary Principle. ICL’s approach to product safety includes evaluating its products and assuming responsibility for them over their entire product life. ICL makes a continuous and consistent assessment of new chemical products prior to commercialization. In addition, existing products undergo an evaluation process at every stage in their production process and the supply chain. The company allocates resources to conduct research and collect data with respect to its products, as required to create a full characterization of the products’ safety features with reference to human health hazards and environmental threats.

Enterprise Risk Management

ICL has established formal and uniform enterprise risk management (ERM) policies and procedures according to the COSO risk management methodology. This process is expected to improve management processes and the company’s ability to reach its goals while protecting the environment and the safety of its employees.

ICL’s ERM activities utilize an integrated business framework and other capabilities to strongly integrate risk management into the company’s business culture. This integration is designed to increase the performance of the different ICL BU’s, to support corporate activity, to minimize exposure to risks and to enable strategic achievements.

A comprehensive risk mapping process was conducted throughout ICL’s diverse organizational units. The mapping included risks associated with ICL’s operations, EHS, product regulation and safety, finance, governance, and others.

ICL’s risk management process is a structured, continuous process and consists of both periodic and ongoing activities. It includes the following five levels of operation:

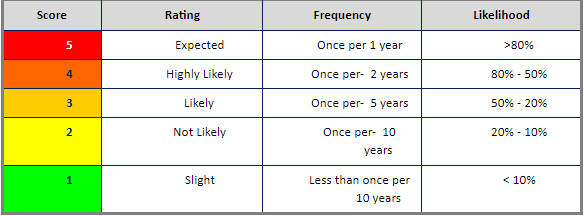

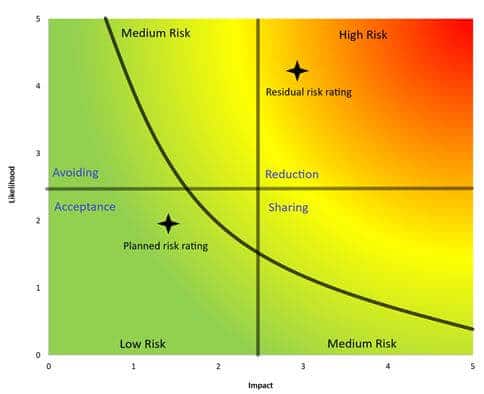

As part of the ERM process, the company defined the likelihood of each risk and its scales of severity. Impact is evaluated in accordance with four major categories: financial, operational, compliance and social license to operate. This provides ICL with the ability to analyze and adjust its action plans according to the highest potential risk.

The magnitude of risk is determined by multiplying the identified impact and likelihood scores. The magnitude is divided into three ranges of management according to the company’s risk matrix.

A mitigation plan is developed for each risk identified in the ERM process and requiring management.

Progress related to risk development and mitigation activities is reported monthly. In addition, this progress is reported semi-annually to the GEC and annually to the BOD.