PolyStyrene Loop: Retrieving Bromine

Launching of the PolyStyreneLoop Project: Circular Economy in Action

Polystyrene foams have long been used as building insulation and as packaging material. They are known for their outstanding insulation and shock absorbing abilities. They are well tried and tested for use in various applications. Used PS foams remain a valuable material source for new raw material and for a variety of products. In the packaging sector, there are already many successful recycling systems in place throughout Europe.

PS foams used for insulation boards contain HBCD, a flame retardant that has been used since the 1960s. HBCD has been the best solution to ensure safety in case of fire and to meet national fire regulations for many years. However, HBCD is now considered a restricted substance. It can therefore no longer be reused. Millions of tonnes of PS foam waste in Europe can no longer be regularly recycled.

The project is an essential contribution to the EU’s efforts to develop a sustainable, low carbon, resource efficient and competitive economy.” Mr. Paolo Sandri

A physio-chemical recycling process can now preserve the high quality PS, to be used as raw material for new foams and safely remove the flame retardant HBCD from PS foam. The HBCD is destructed in ICL’s hazardous waste incinerator at the company’s Terneuzen site, equipped with a Bromine Recovery Unit (BRU). This facility ensures the safe recovery of the valuable bromine component. The recovered Bromine is re-used for producing new brominated polymeric flame retardants like FR-122P, which are then incorporated in new PS foams used for insulation to meet fire safety standards.

Blue Tulip Awards

The PolyStyrene Loop project won the Blue Tulip Award 2020 in the climate category. The Blue Tulip Award identifies the most promising startups and innovations in the Netherlands across 8 categories. The expert jury recognized the innovative technology behind PolyStyrene Loop, its disruptive business model as a cooperative and the scalable solution with impact that brings the circular economy in action.

The innovative PSL project employs a ground-breaking technology to separate the recently restricted chemical, HBCD, from PS foam waste, while also allowing for the recovery of bromine, which can then be used again for the production of new flame retardants, such as FR-122P produced in ICL Terneuzen and Neot-Hovav. This technology has already been included in the Technical guidelines under the UNEP Basel Convention as a best available technology to handle HBCD-containing waste.

The PSL project goal is to simultaneously enable the recycling of PS foam waste, the treatment and destruction of HBCD residues, and the recovery of bromine in line with the new European POPs (Persistent Organic Pollutants) regulation. This will be accomplished through an innovative recycling process of 3,000 tonnes of PS per year, and through organizing the value chain by means of a collaborative model, which will hopefully trigger further replication throughout Europe.

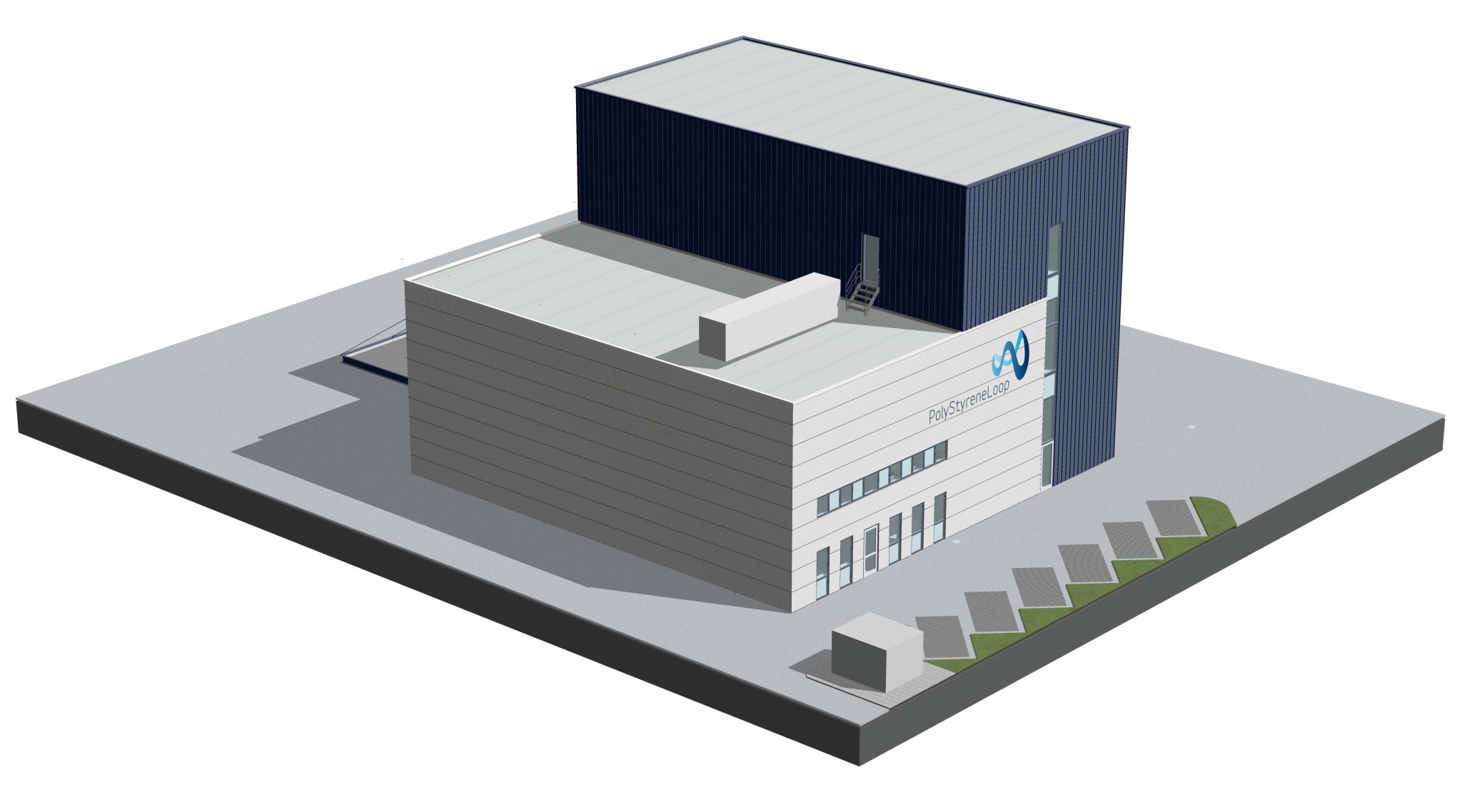

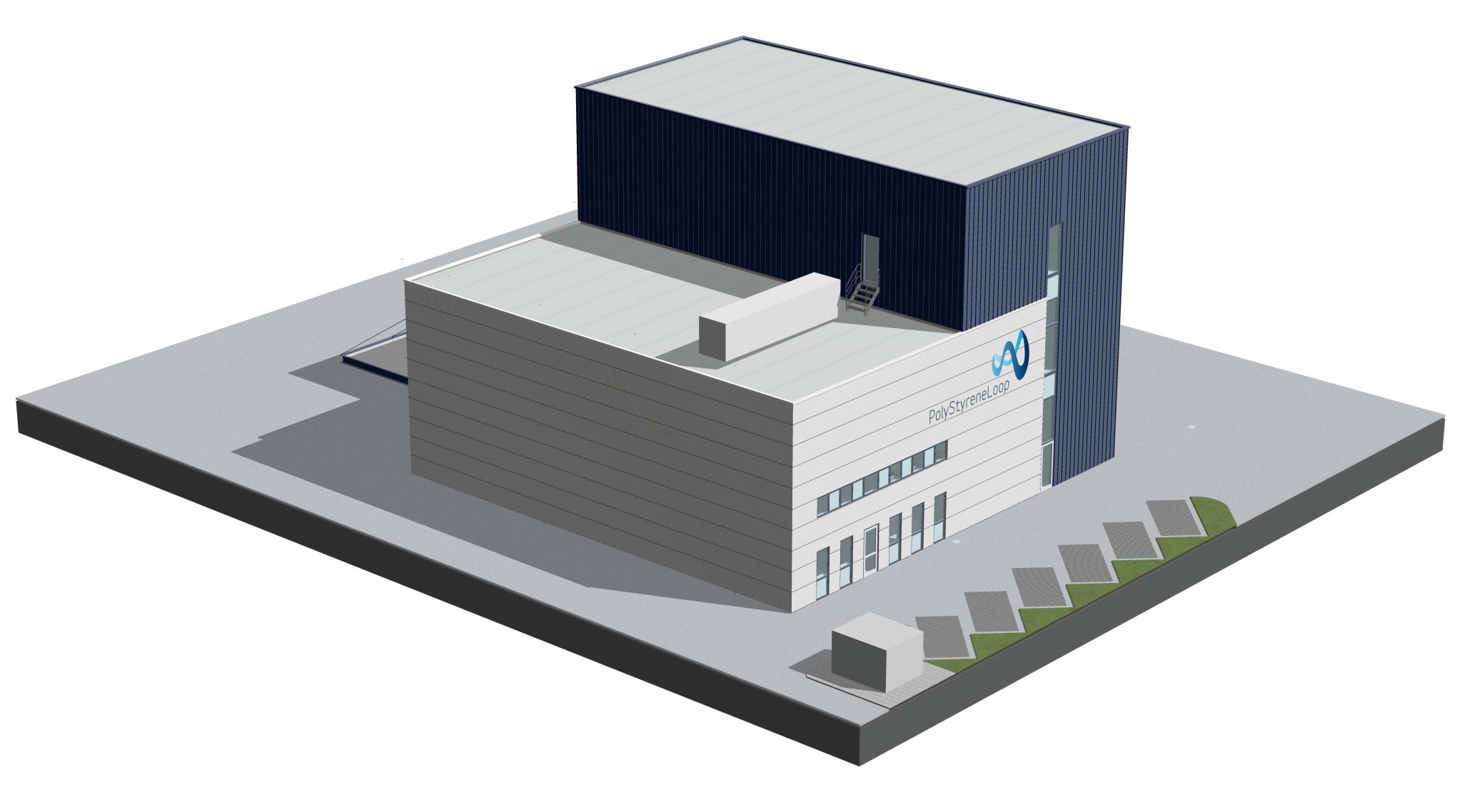

The PolyStyrene Loop large-scale demo plant is being built and the aim is to begin operations in 2021 and have the capacity to treat up to 3,300 tonnes of PS waste per year. Once up and running, the PolyStyrene Loop project will be able to cope with incoming PS foam waste streams and produce a high-quality result that could be used in new PS foam insulation installations. The planned demonstration plant will be set-up in Terneuzen, Netherlands, adjacent to the ICL site, and will work with the CreaSolv® Technology.

As an industrial pioneer project promoting Circular Economy, the PSL project will help the EU deal with over 20 million tonnes of expected insulation waste material containing HBCD, which will need to be disposed of in the next 50 years. Recycling PS foam typically saves as much as 50% CO2 emissions (compared to using it for energy recovery via incineration). This technology offers an additional contribution to resource efficiency at the end of life phase for PS foam insulation, on top of the CO2 emissions already saved by reducing energy consumption during the long use phase of a building.

It encourages industry-led and market-based initiatives to be carried out with all partners along the value chain. It is a signal to other polymer producers that the cooperation can lead to more circularity and sustainability”

Mr. Paolo Sandri speaking on behalf of the Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs of the European Commission.

The PolyStyrene Loop Cooperative is a non-profit organization, initiated by ICL and Synbra Technology under Dutch law. More than 70 members of the initiative are industry representatives from the whole polystyrene foam value chain, many of which are SMEs (small-medium enterprises): PS foam manufacturers, raw material and additives suppliers, foam converters, and recyclers. The initiative was set up to demonstrate the technical and economic feasibility of recycling polystyrene (PS) insulation foam waste and the recovery of bromine. The PolyStyrene Loop project demonstrates how the polystyrene value chain meets the fundamental requirements of a circular economy, by ensuring a technically, economically and environmentally sustainable closed-loop recycling system.